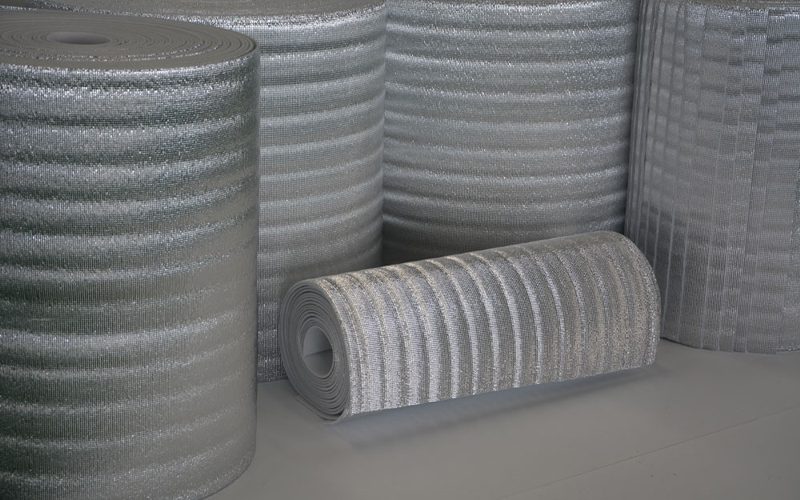

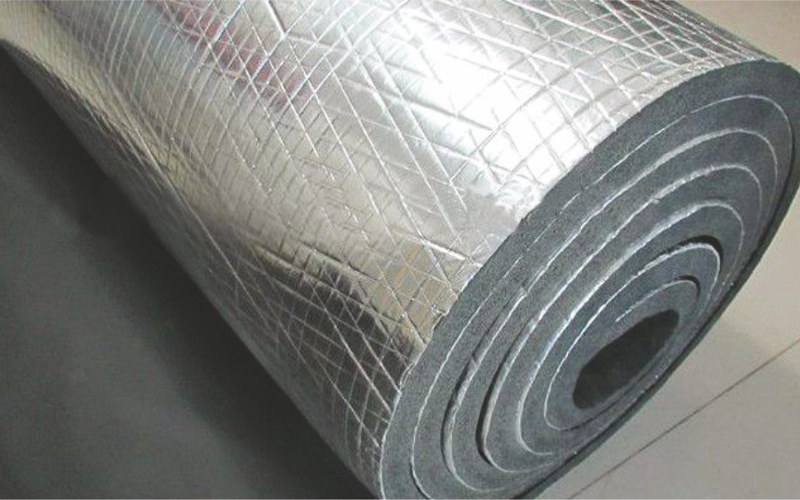

Insufoam

Insufoam

Advantages

Insufoam is a product that is widely used in roofing solutions all over the world; when applied and used in industrial or residential projects, it provides the following benefits:

- Keeps room temperature low and improves energy efficiency of buildings

- Saves energy and cost

- Noise reduction from heavy rain

- Eco friendly due to the recyclable nature of the product

- Insufoam is safe to use. The substance used to make Insufoam is the same as that used in the food sector.

- Installation is simple, and the product has a lengthy life span.

- Fire retardant grade can be produced on request

Product Dimensions

| Standard Sheet | ||||

|---|---|---|---|---|

| Thickness (mm) | Reflective Mat | No. of sheet/pack | Width (meters) | Length (meters) |

| 5 | MPET/Aluminum foil | 20 | 60 | 60 |

| 10 | 10 | 60 | 60 | |

| Standard Insufoam Roll | ||||

|---|---|---|---|---|

| Thickness (mm) | Reflective Mat | Width (meters) | Length (meters) | |

| 3,4,5 | MPET/Aluminum foil | 0.9 | 100 | |

| 10 | 0.9 | 50 | ||

| 15,20,25 | 0.9 | 50,25 | ||

| 50 | 0.9 | 25 | ||

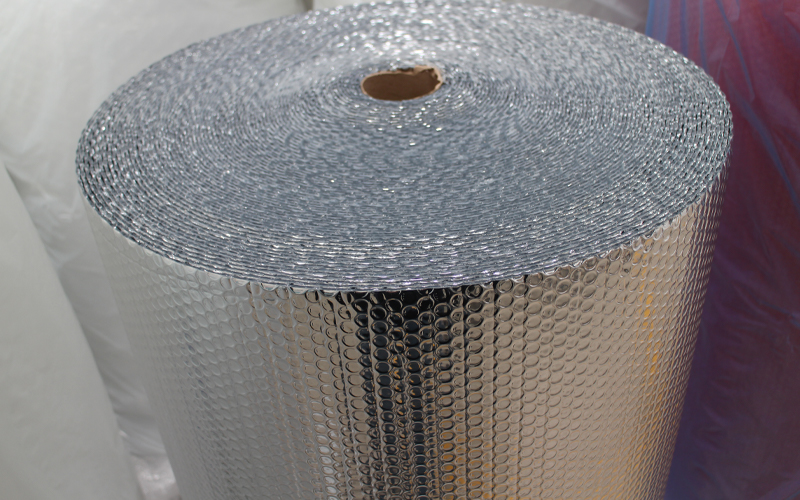

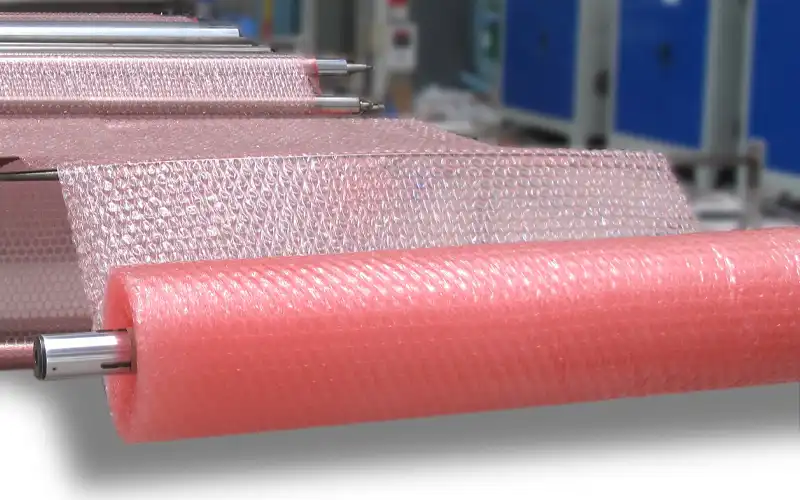

| Standard Insububble Roll | ||||

|---|---|---|---|---|

| Thickness (mm) | Reflective Mat | Width (meters) | Length (meters) | |

| Insububble + MPET 2 Sides |

MPET | 0.9 1.2 |

100 60 |

|

| Insububble + ALU 2 Sides |

Aluminum Foil | 0.9 1.2 |

100 60 |

|

| Insubbuble + MPET + ALU | MPET+Aluminum Foil | 0.9 1.2 |

100 60 |

|

Physical Properties of Insufoam

| CHARACTERISTIC | TEST RESULT | METHOD |

|---|---|---|

| DENSITY | 20 -60 Kg/m3 | ISO 845 1988 (E) |

| REFLECTIVITY ALU FOIL | 0.97 | ASTM E408 |

| EMISSIVITY ALU FOIL | 0.03 | ASTM C1371 |

| UV RESISTANT | EXCELLENT | - |

| CHEMICAL RESISTANCE | EXCELLENT WITH AL FOIL | ASTM D-543/BS 4618 |

| TEMPERATURE RANGE | -80 oC TO 90 oC | - |

| FLEXIBILITY RANGE | EXCELLENT | BS4433 |

| HEAT RESISTANT (R-VALUE) | 3.0 m2 C/W | ASTM C236 |

| THERMAL CONDUCTIVITY | 0.030 Kcal/m2 hr oC | ASTM C-177 |

| WORKING LIFE | 8-10 YEARS | - |

| FLAMMABILITY | HF-1 | UL-94 |

| CHARACTERISTIC | TEST RESULT | METHOD |

|---|---|---|

| DENSITY | 100 GSM | ISO 845 1988 (E) |

| REFLECTIVITY ALU FOIL | 0.97 | ASTM E408 |

| EMISSIVITY ALU FOIL | 0.03 | ASTM C1371 |

| UV RESISTANT | EXCELLENT | - |

| CHEMICAL RESISTANCE | EXCELLENT WITH AL FOIL | ASTM D-543/BS 4618 |

| TEMPERATURE RANGE | -80 oC TO 90 oC | - |

| FLEXIBILITY RANGE | EXCELLENT | BS4433 |

| THERMAL CONDUCTIVITY | 0.020 Kcal/m2 hr oC | ASTM C-177 |

| TENSILE STRENGTH | 160.2 -175.3 | JIS K 6767 |

| COMPRESSION STRENGTH | 0.35 - 0.45 KG/m | ASTM D-3575 |

| WATER ABSORPTION (mg/cm3) | less than 1.8% after 28 days | ASTM D-1677 |

| WORKING LIFE | 8-10 YEARS | - |

| FLAMMABILITY | HF-1 | UL-94 |